Roll Solutions

A roll tissue production line is a manufacturing system designed to convert large parent rolls of tissue paper into smaller finished rolls or other tissue products, such as toilet paper, paper towels, or AFH products.

Here is a general overview of the typical stages involved in a roll tissue production line:

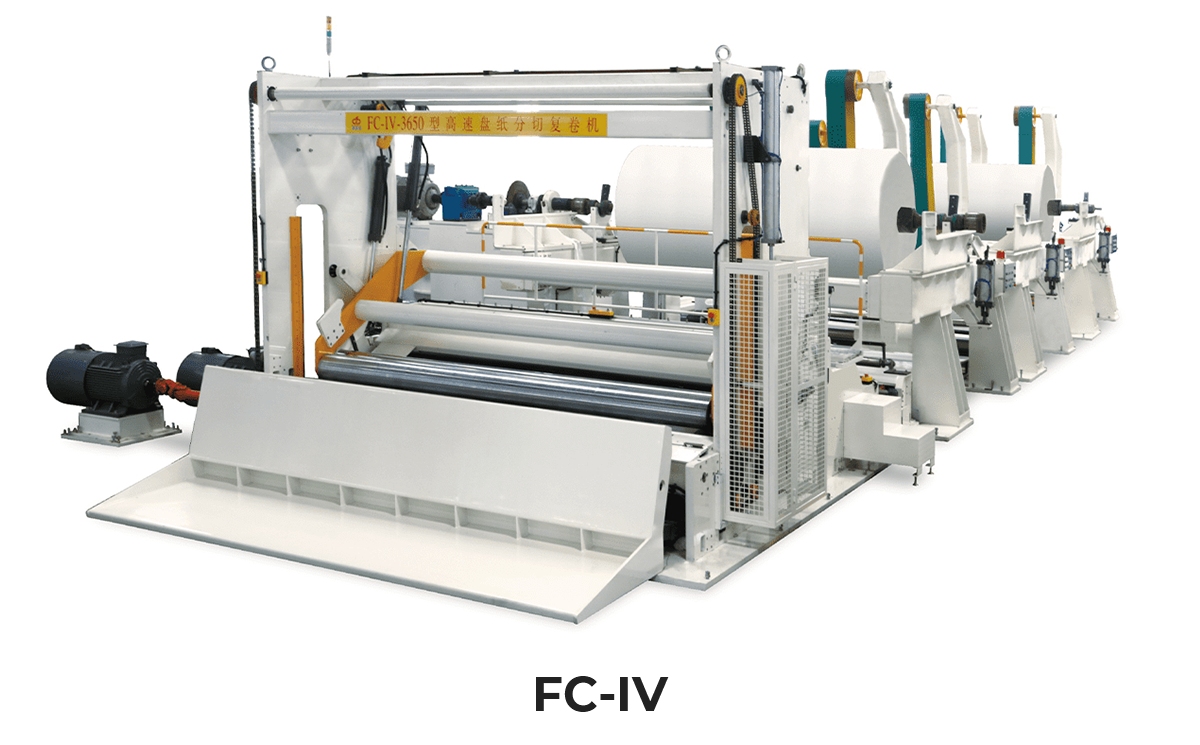

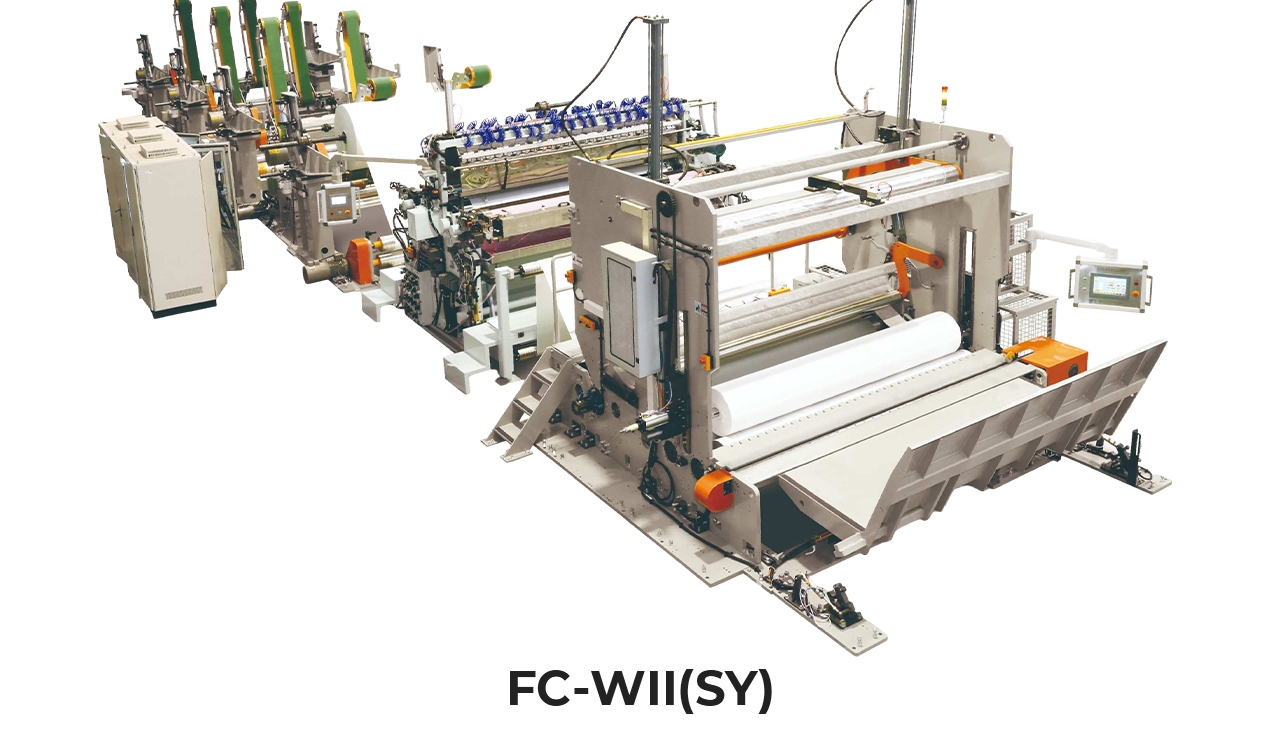

1.Unwinding: The large parent rolls of tissue paper, also known as jumbo rolls, are placed on unwinding stands or spindles. The unwinding process involves slowly unwinding the parent roll while maintaining tension and controlling the speed to ensure a continuous and controlled feed of the paper.

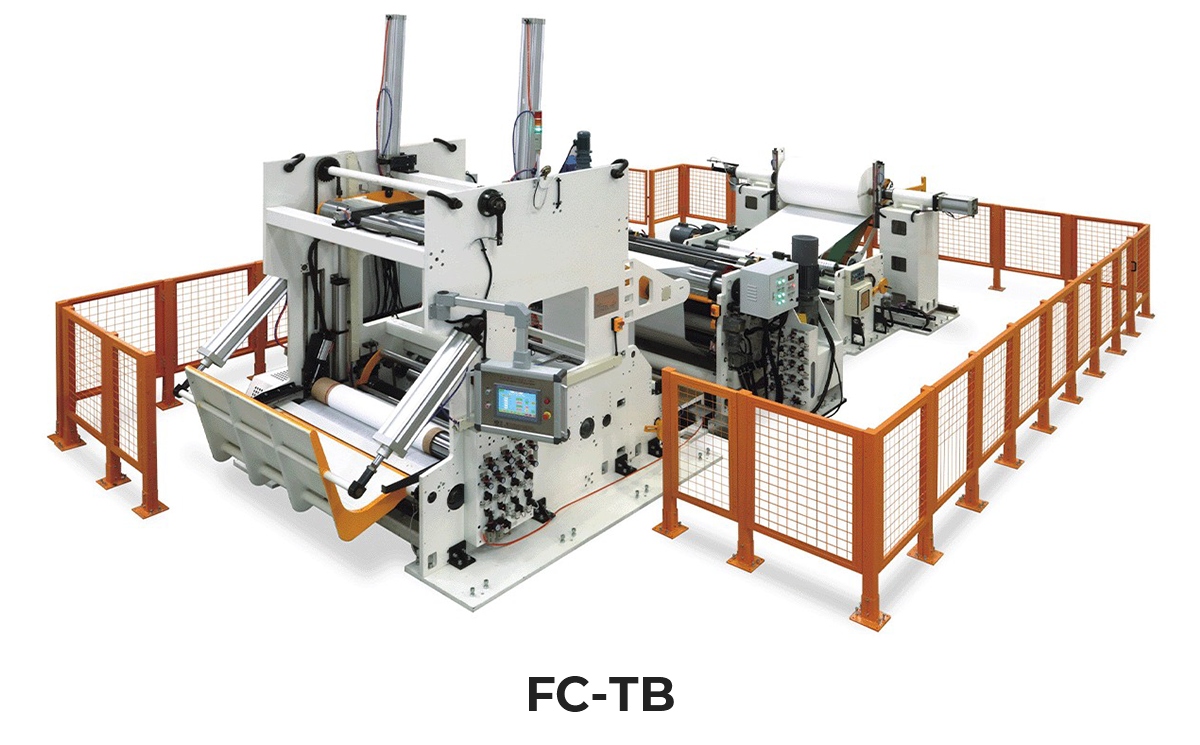

2.Embossing: If desired, the paper may go through an embossing process where a pattern is pressed onto the surface of the paper. Embossing can enhance the softness, appearance, and absorbency of the tissue paper. Embossing rolls with raised patterns are used to imprint the desired texture onto the paper.

2.Perforating: Perforation unit is used to create perforated lines across the width of the tissue paper. These perforations allow for easy tearing and provide convenient sheet sizes for the end users. Perforation patterns can vary depending on the intended product.

3.Rewinding: The embossed, and perforated tissue paper is rewound into smaller rolls. Rewinding machines unwind the slitted paper and wind it onto individual cores to create finished rolls. The rewinding process ensures proper tension, alignment, and tightness of the wound rolls.

4.Tail Sealing: Once the smaller rolls are rewound, a tail sealing process is often employed to secure the end of the roll and prevent it from unraveling. This can be done by applying glue or using non-glue sealing methods.

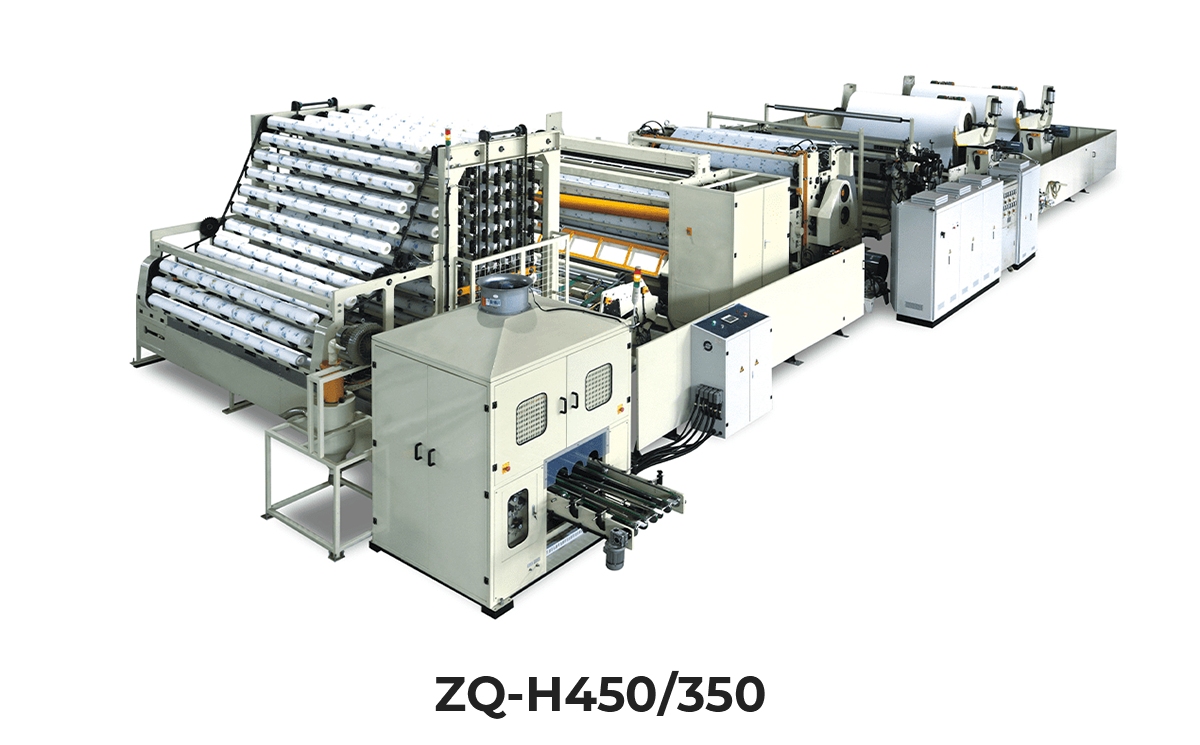

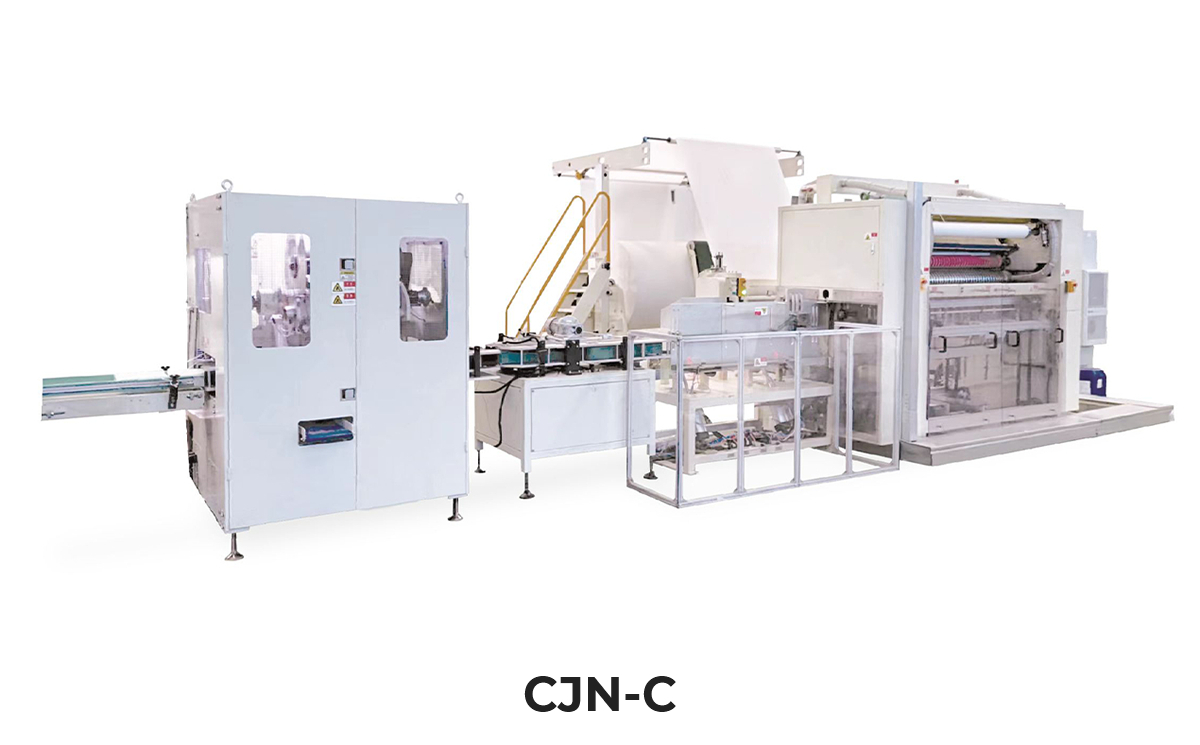

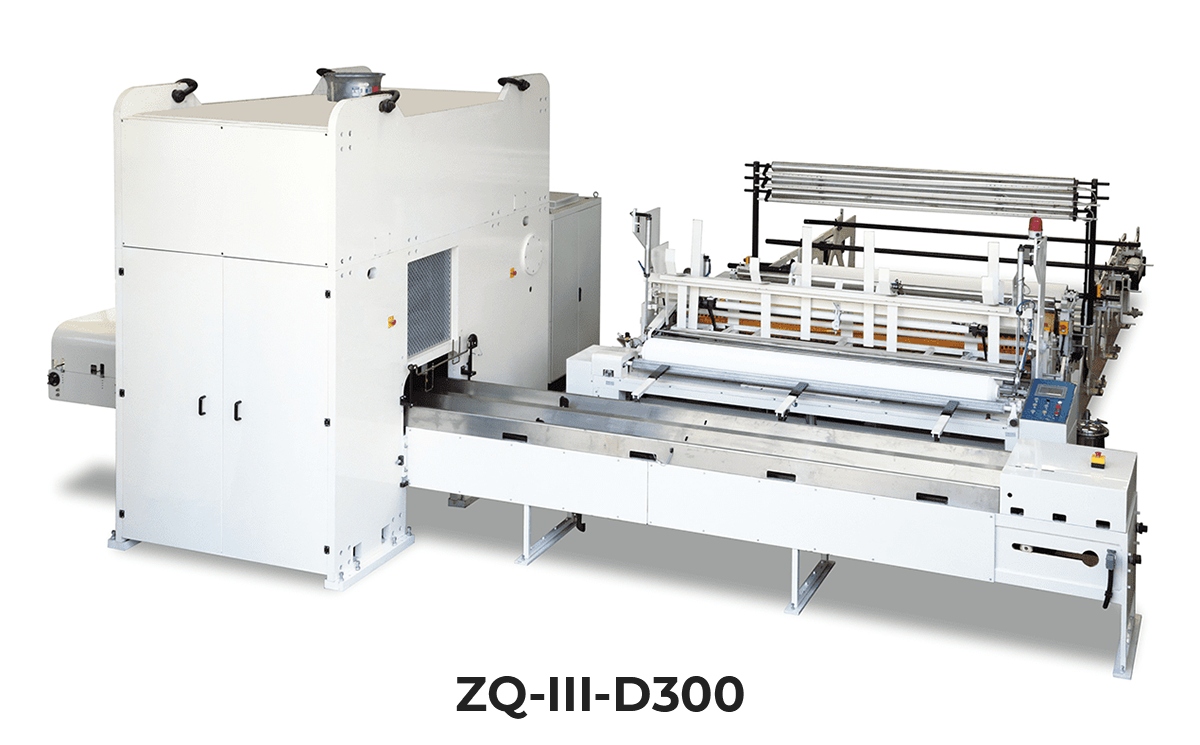

ZQ-III Series Fully-automatic Roll Production Line

ZQ-III Series is designed to make toilet roll, kitchen towel or JRT. It can maximize productivity, efficiency, and quality while minimizing manual labor and human intervention. It enables high-speed production, consistent product specifications, and streamlined workflow, meeting the demands of the tissue industry.

1.Adopt PLC&HMI, easy to operate the machine.

2.Each part is driven by independent variable frequency motor and synchronous belt,which guarantee the perforation and total length accuracy.

3.Electric & pneumatic controlled brake is much more steady and faster.

4.Automatic tail trimming gluing sealing.

5.Multipurpose production line:it could also process JRT products.

| Max width of raw paper | 2150mm-2800mm, others please specify |

| Max outer diameter of raw paper | 1500mm, others please specify |

| Design speed | 0-250m/min |

|

Outer diameter of finished product |

65mm-300mm,others please specify |

|

Outer diameter of finished product core |

25mm-80mm, others please specify |