Jumbol Reel Solutions

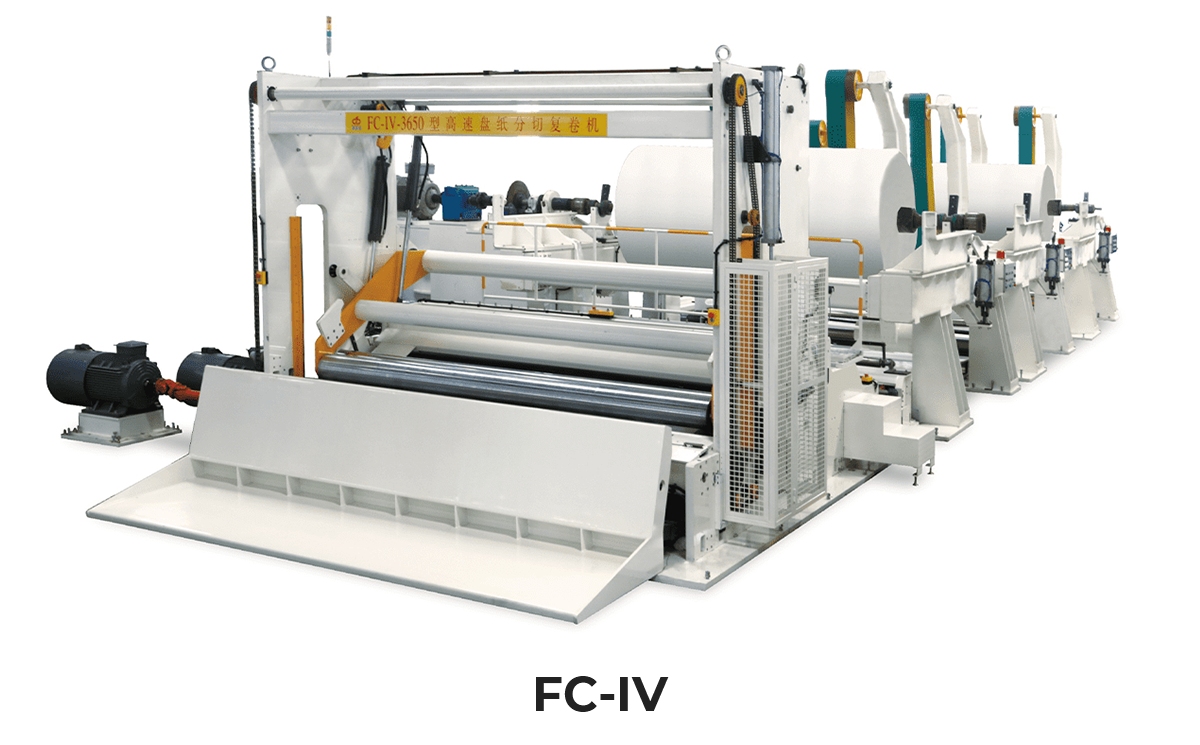

In the field of modern industrial production, paper rolls are widely used. There are also many ways to process paper rolls, one of the important ways is to cut raw paper. Raw paper slitting is a basic technology of paper roll processing, which essentially divides large-format paper into small-format paper. When cutting raw paper, an important machine is the raw paper cutting machine.

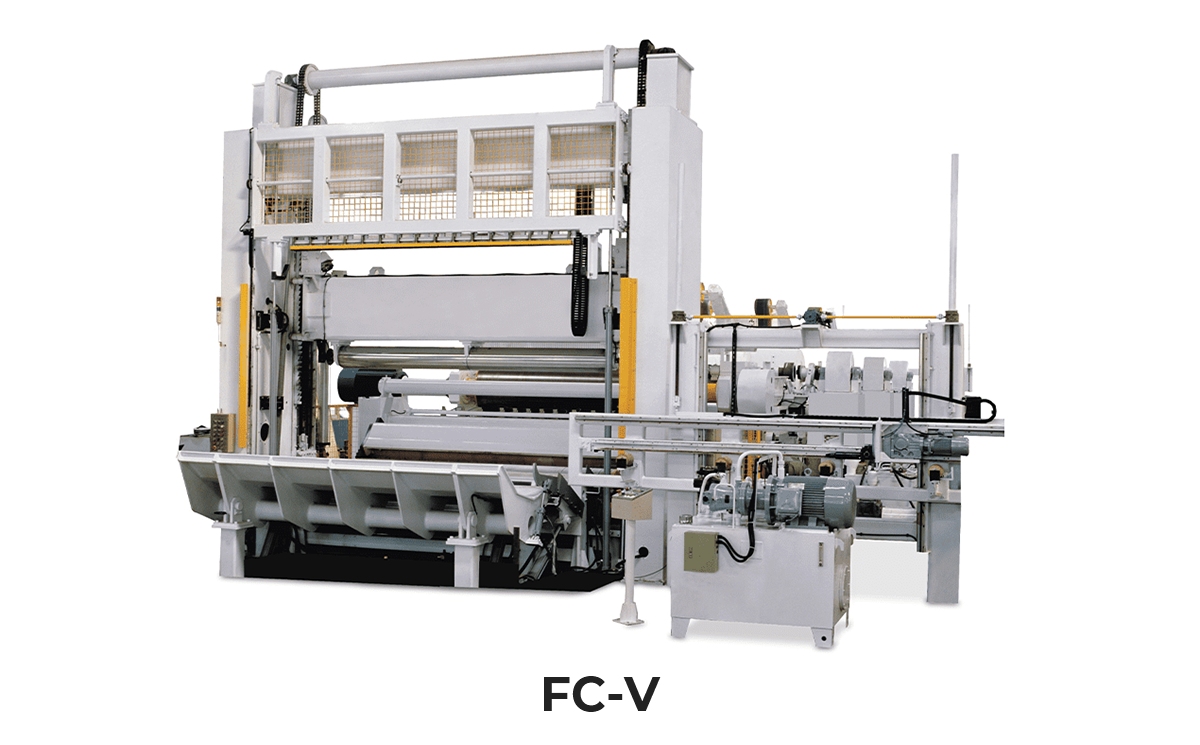

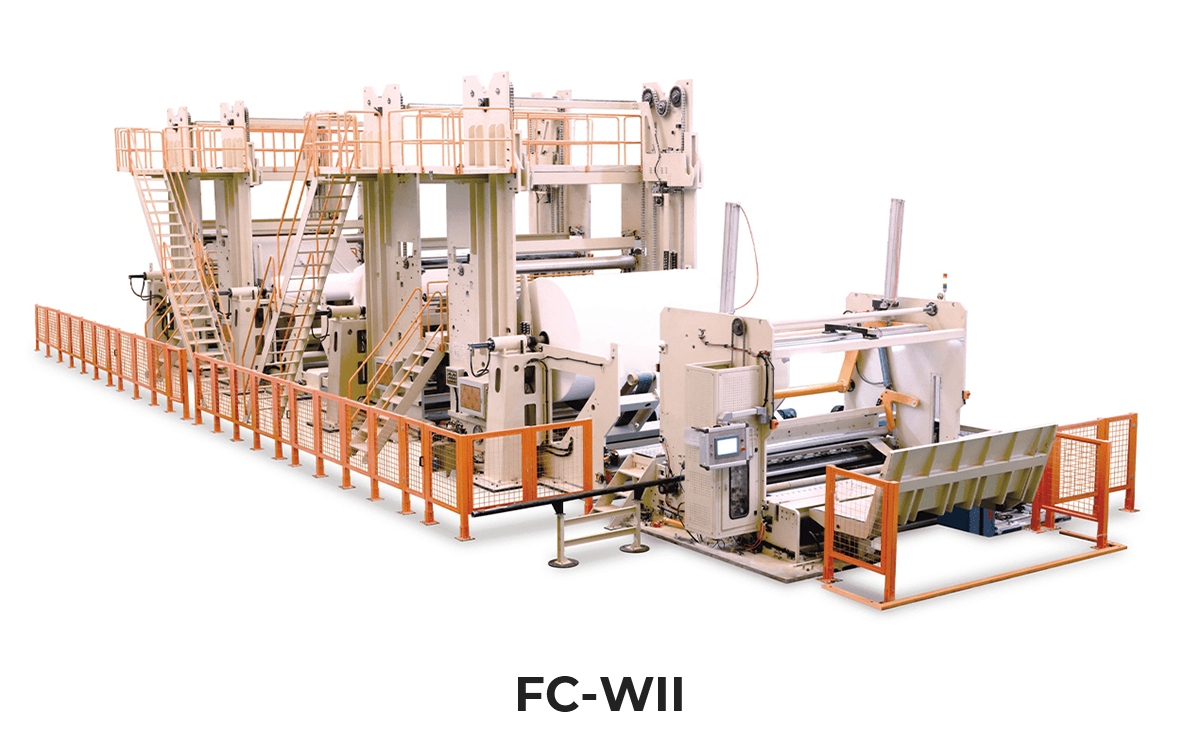

FC series

1.Rewinding control: Automatic pneumatic proportional valve controls linear slider rail lifting, hydraumatic servo system controls riding roller,pneumatic thimbles grasp core shaft;

2.Slitting bottom blade: one piece blade shaft equipped with full sets of multi-blade blade sets;

3.Front&back rewinding rollers' speed differential and riding roller,control final product's tension and both ends' neatness;

4.Backstand: Could run both forward and reverse,easy to operate the machine; Independent driven guiding roller,and the web guide platform at the bottom,reduce the loss of elongation;

5. Leading calender technology (optional): Steel to steel calender,both two roller are made of chilled cast iron, are driven by two motor respectively; Use pneumatic tyre increase pressure; calender rollers' relative angle and gap size are both adjustable;

6. Tipper-hopper does guarding job (while machine is running); Use water does tail trimming job;

7. Automatic rewinding shaft feeding function;

8. Hydraulic control riding roller, pneumatic lifting reel core shaft;

9.Centre drive unwinder, with web-tension sensor, could process packaging paper and cultural paper

10.Automatic pull-plug system (optional): easy to operate the machine, improves efficiency;

| Max width of raw paper | 2900mm-4200 |

| Max outer diameter of raw paper | 3000mm, others please specify |

|

Max outer diameter of finished product |

1800mm-2300mm |

| Design speed | 0-1500m/min |

|

Application |

Tissue paper, packaging paper or cultural paper |